Monday, January 30, 2006

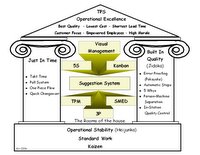

TPS House

I'm probably not as up on LEAN as other people on the call. Since Juergen has been referring to the Toyota Production System (TPS) House, I figured I should find a reference. Plenty of those available.

I created a composit from multiple references. Some of those were:

- EMS Consulting Group

- Gemba Group

- A research report on LEAN Ship building

- and, Juergen had a presentation last November.

Comments:

<< Home

Hello Bob,

First of all I would like to acknowledge that you are extremely supportive to our group!

I am looking forward meeting you in LA…and you know what, I will pay for the first round!!

Regarding the Toyota House(s), yes there are many different ones around. Even at Toyota itself I found two (2) differ ones.

The most common one uses the two pillars:

1. JIT

2. Autonomation (automation with a human touch)

I found one that separated and highlighted the People aspect as one pillar.

That is more my view, since “Autonomation” (e.g. poke yoke) for me still belongs to the processes themselves, so I moved it to the left and called it “Process (Improvement)”.

The second key pillar is clearly around the People and People Engagement.

I think for Toyota and Japan their house is OK, since the People issue is not really and issue, it’s more in the Japanese culture. For the Western World it is “THEEE” issue, that stops getting sustainable results. So, form my point of view it needs a separate pillar.

For the middle part (between the tow pillars), I don’t see this as the placeholder for the tools. It is the section where results from the two pillars on the left and right and form the foundation emerge. This is the center, which means that’s were the “Culture” is created that drives e.g. continuous improvement.

Basically, I like my TPS house for the Western World – at least for the time being.

All the Best Bob!!

Regards,

Juergen Boenisch

Executive Management Consulting

Post a Comment

First of all I would like to acknowledge that you are extremely supportive to our group!

I am looking forward meeting you in LA…and you know what, I will pay for the first round!!

Regarding the Toyota House(s), yes there are many different ones around. Even at Toyota itself I found two (2) differ ones.

The most common one uses the two pillars:

1. JIT

2. Autonomation (automation with a human touch)

I found one that separated and highlighted the People aspect as one pillar.

That is more my view, since “Autonomation” (e.g. poke yoke) for me still belongs to the processes themselves, so I moved it to the left and called it “Process (Improvement)”.

The second key pillar is clearly around the People and People Engagement.

I think for Toyota and Japan their house is OK, since the People issue is not really and issue, it’s more in the Japanese culture. For the Western World it is “THEEE” issue, that stops getting sustainable results. So, form my point of view it needs a separate pillar.

For the middle part (between the tow pillars), I don’t see this as the placeholder for the tools. It is the section where results from the two pillars on the left and right and form the foundation emerge. This is the center, which means that’s were the “Culture” is created that drives e.g. continuous improvement.

Basically, I like my TPS house for the Western World – at least for the time being.

All the Best Bob!!

Regards,

Juergen Boenisch

Executive Management Consulting

<< Home